You want to deck out your staff in new work uniforms or get your logo on some promotional pens, but don’t know where to start? We get it! There are so many different types of printing and branding methods on offer it can get confusing. So how do you choose?

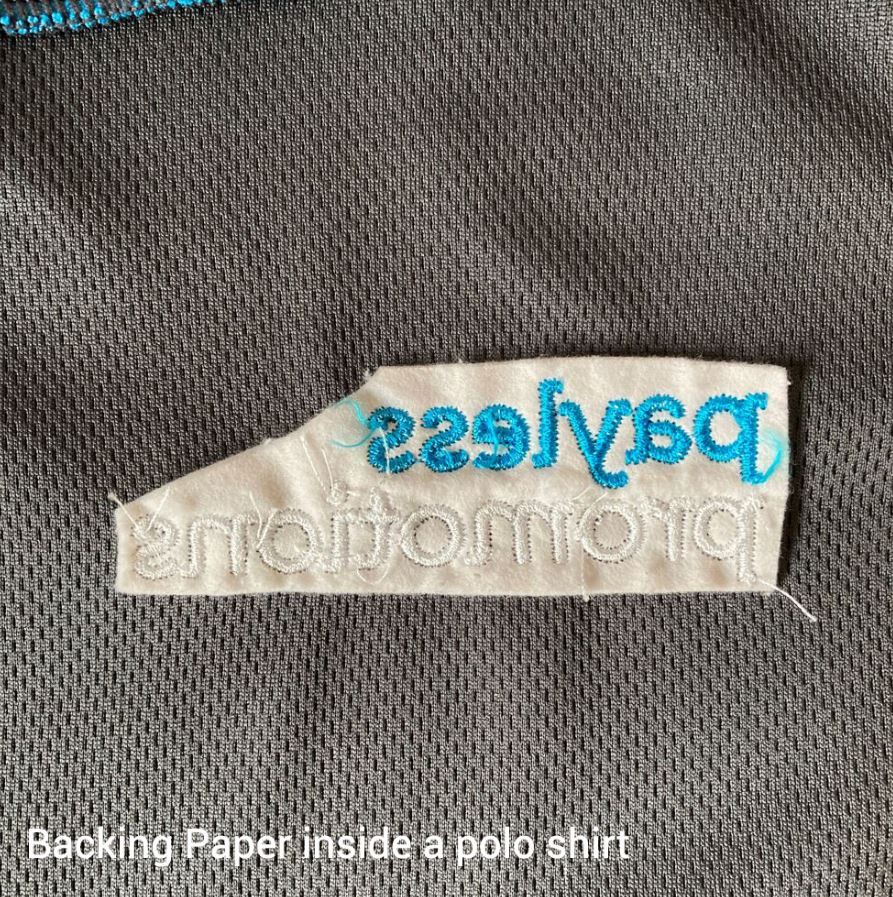

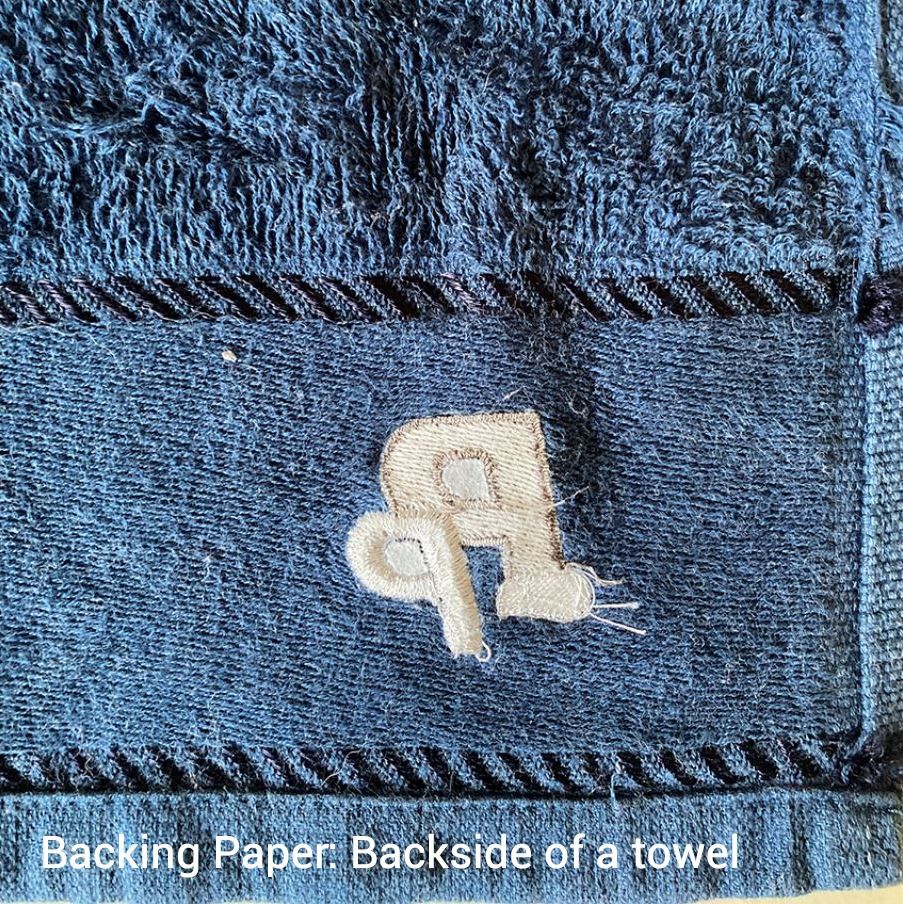

We’ve put together a list of over 20 different printing methods available right here at Payless Promotions. We have also provided the pros and cons of each and when they are best suited. You can now make sure that your branding hits the mark and stands out from the crowd.

Popular on Clothing:

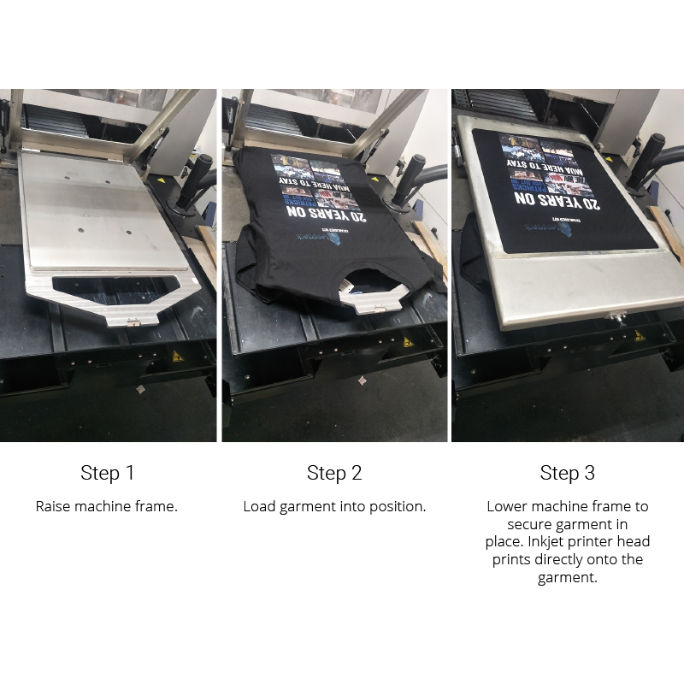

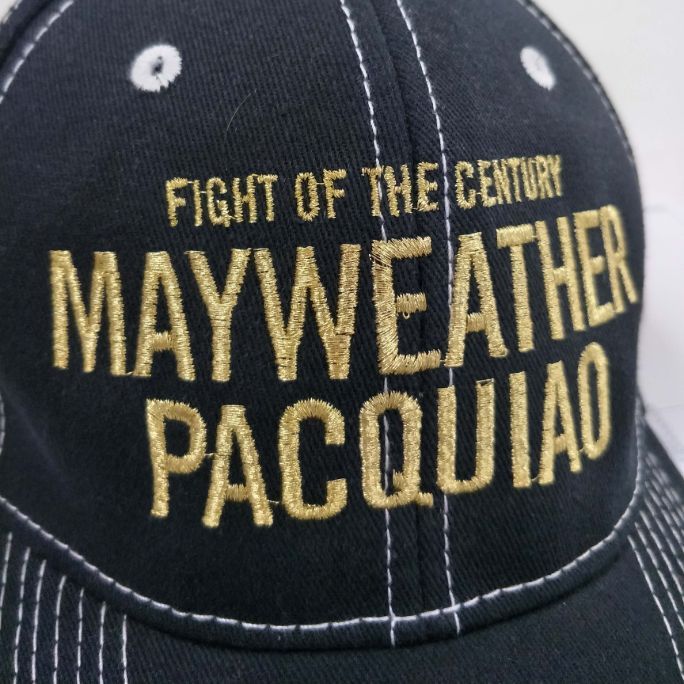

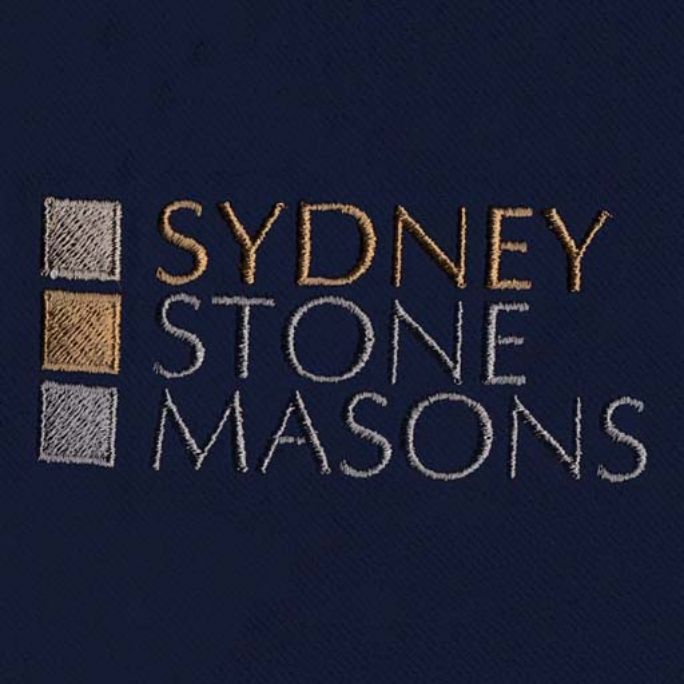

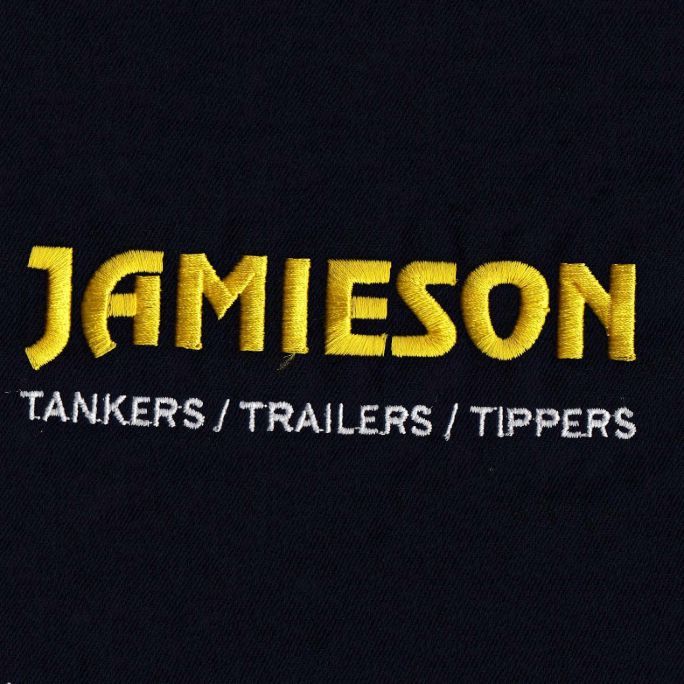

Embroidery, Screen Print, Digital Transfer and Direct to Garment

Popular on Promotional Products: